HOME PAGE

A Game-Changing Approach to Low Head Hydro Power Generation

Thinking Inside The Box

When ATS observed the present state of hydropower design and was considering entering the field, the common response was that Hydro was a Mature Industry and for any chance of success we better think “Outside the Box”. A review of the industry revealed that it consisted of many “boxes patched together” that produce a heavy weight system with large footprint and heavy foundation and powerhouse, at high cost.

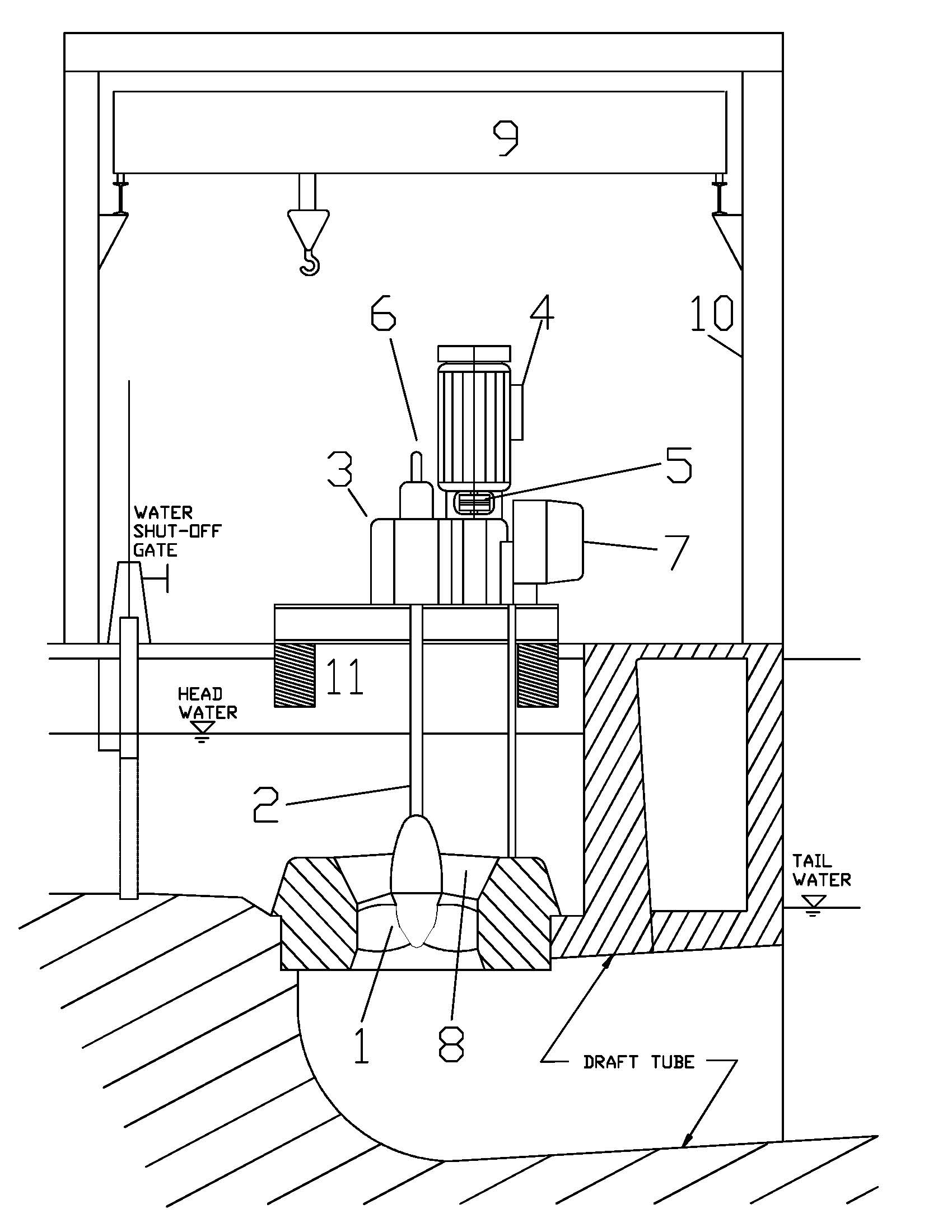

(Fig.1 below)

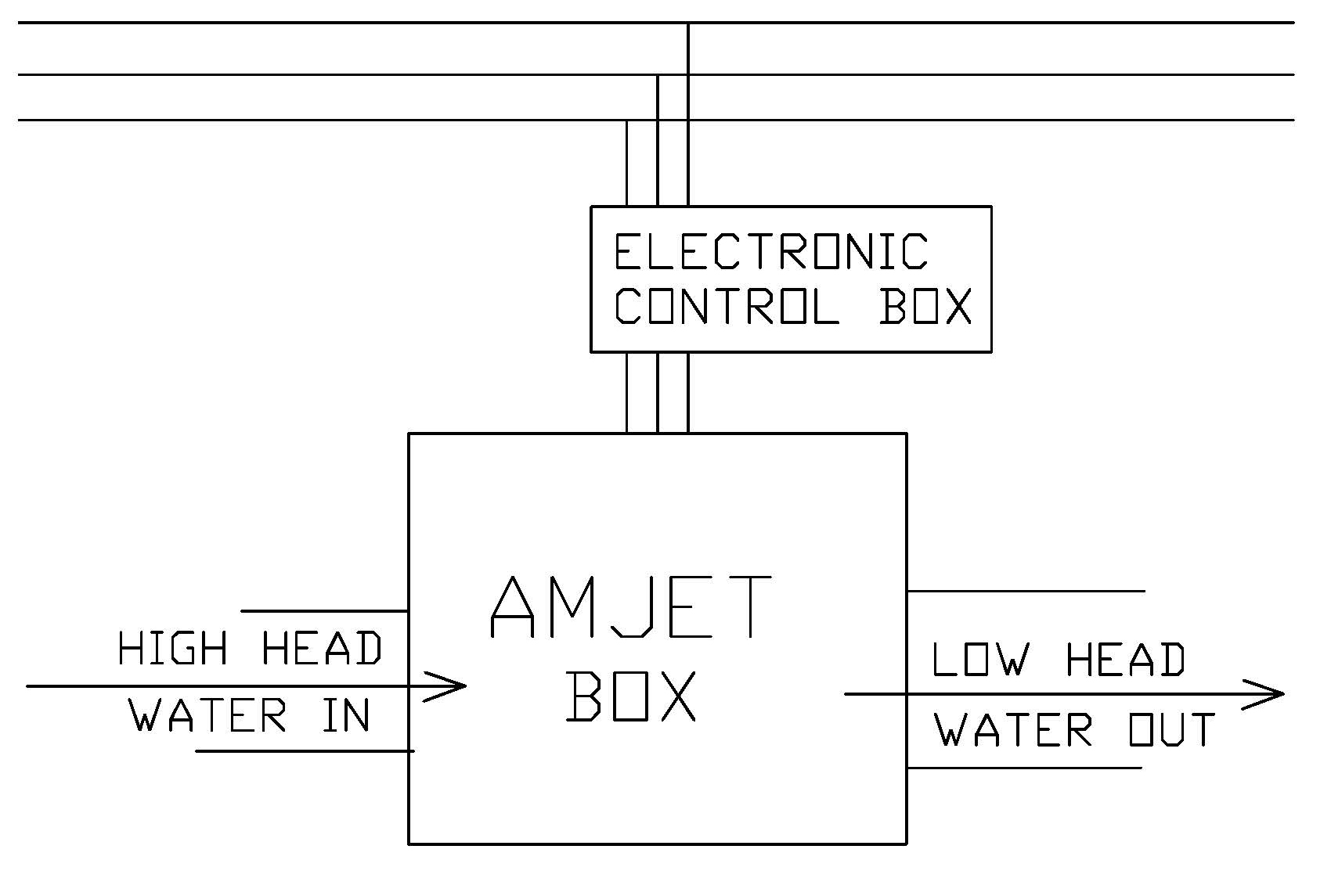

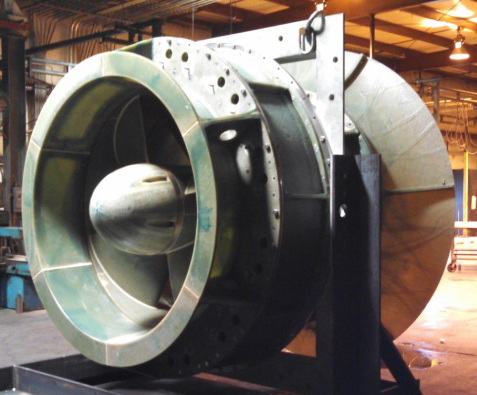

The ATS approach became to search out different technologies and combine them and avoid the traditional “boxes”, thinking “Inside the Box” and create ONE BOX containing all mechanical, hydrodynamic and power generating functions of these traditional boxes and simplify these functions by reducing the number of moving parts to ONE. (Figs. 2-3)

Result:

Eliminating (Fig.4) drive shaft(2), mechanical flow controls: wicket gates(8) and controllable pitch runner(1) the related hydraulics(6), the gear speed increaser(3), a separate generator(4), the generator coupling(5), the governor and synchronizing switch gear(7), civil works and heavy foundation to support and hold in alignment all separate components(11), overhead crane to lift, install and service components(9) and a powerhouse building to contain all of the above(10).

Reducing (Fig.5) mass and footprint 3X to 5X; time to replace or service to ONE day with built-in lifting guide(12); cost and weight by composite construction for lower; mass produced, with per-application power selection at final assembly.

Conventional

Fig. 1

Conventional

Fig. 4 Conventional System

AMJET

Fig. 2

Fig. 3 THE AMJET BOX (ATS-63 composite turbine housing with integrated generator)

Fig. 5

The ATS System

WATCH VIDEO INTRODUCING THE AMJET CONCEPT

Then visit TECHNICAL DETAILS