APPLICATIONS

All applications are affected by the low weight, small footprint, axial flow-through

design of the unit, resulting in greatly simplified and lower cost applications:

-- lower hardware cost -- lower installation cost -- shorter hardware delivery --- shorter installation time -- one-day service/replacement – reduced maintenance cost -- improved capacity factor -- ATS turbine/generators can be

deployed in locations not possible with conventional equipment.

Installation examples

1)—New installations

Example: Bulkhead installation

Fig. 10 shows turbine on weir, left in operating position, on the right the same weir with unit in service position.

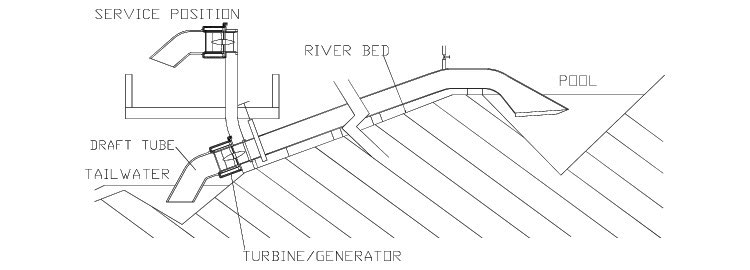

Example: Run-of-river installation

Fig. 11 This application makes use of the natural river drop, the penstock lying in the river bed or buried in the river bank.

A siphon may be used to bring the conduit over small heights.

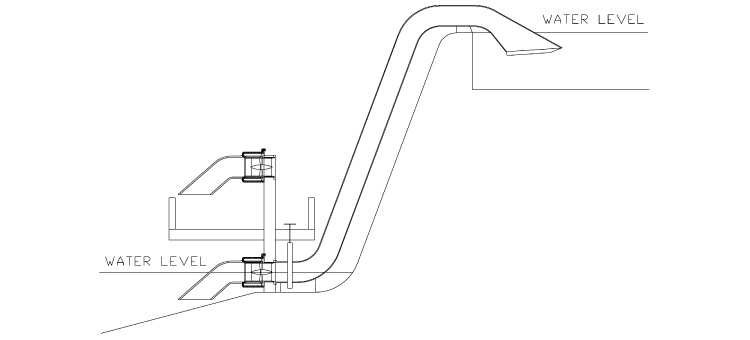

Example: Siphon Installation

Fig.12 The siphon installation relies on either a pump or vacuum pump to start the turbine running. The ATS turbine/generator may be wired to also function as a motor and start the waterflow in reverse to prime the siphon.

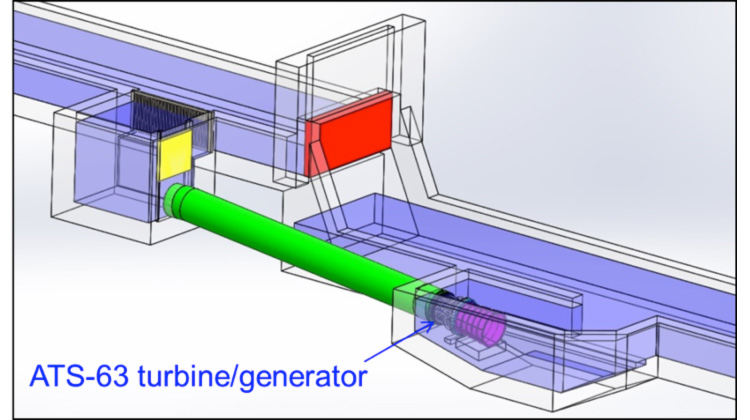

Example conduit installation

Fig.14 The depicted Irrigation canal drop installation does not interfere with the canal flow control function.

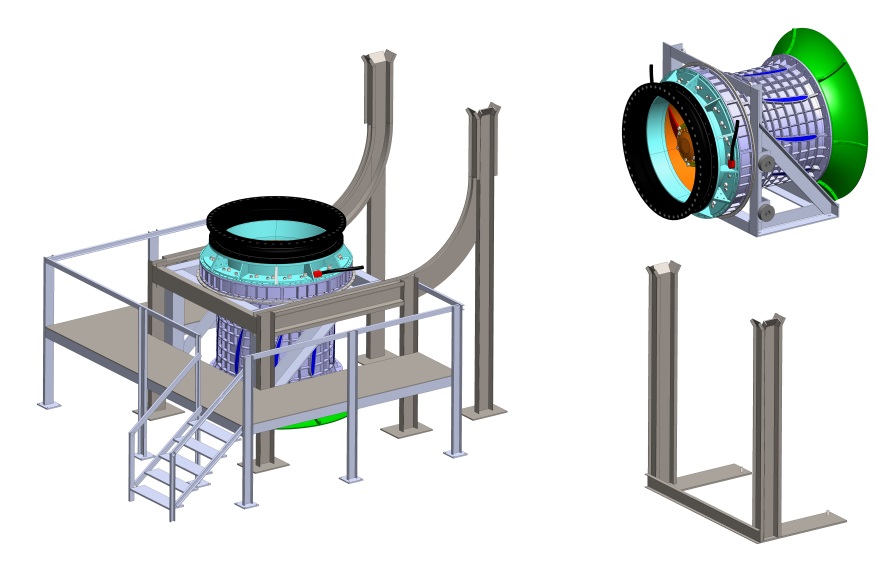

Example Horizontal shaft in-line placement with service stand

Fig.15 Any horizontal shaft turbine installation couples the penstock or bell housing to the intake (right) side and the draft tube to the discharge side of the

Turbine/generator that lowers in a track to align flanges.

The service stand rotates the unit service-side-up for easy access.

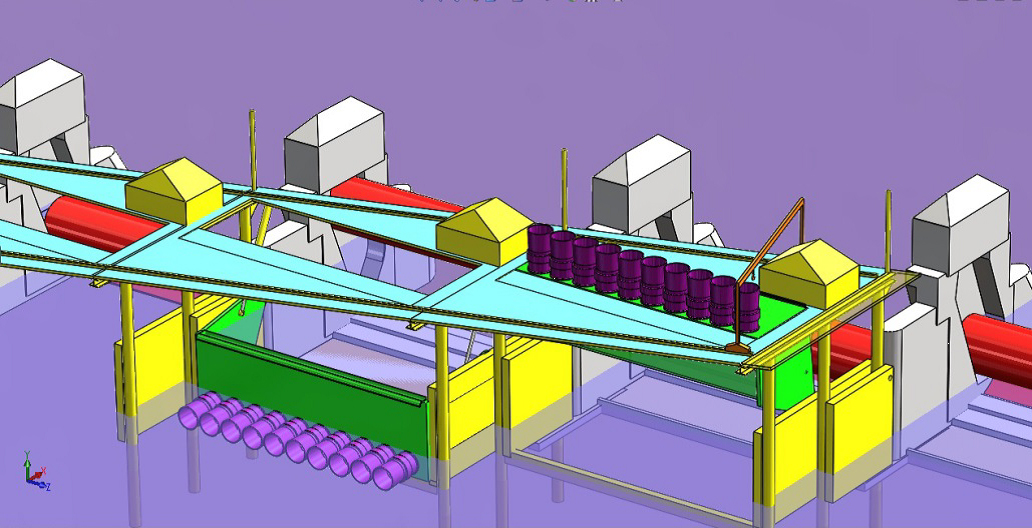

Example multiple turbine installations (patented)

Fig.16 Large river dams require multiple units to recover energy efficiently and without disturbing the existing dam. Barriers carry multiple turbine/generators and can raise above the flood line in the maintenance position.

2) - Dam Retrofits

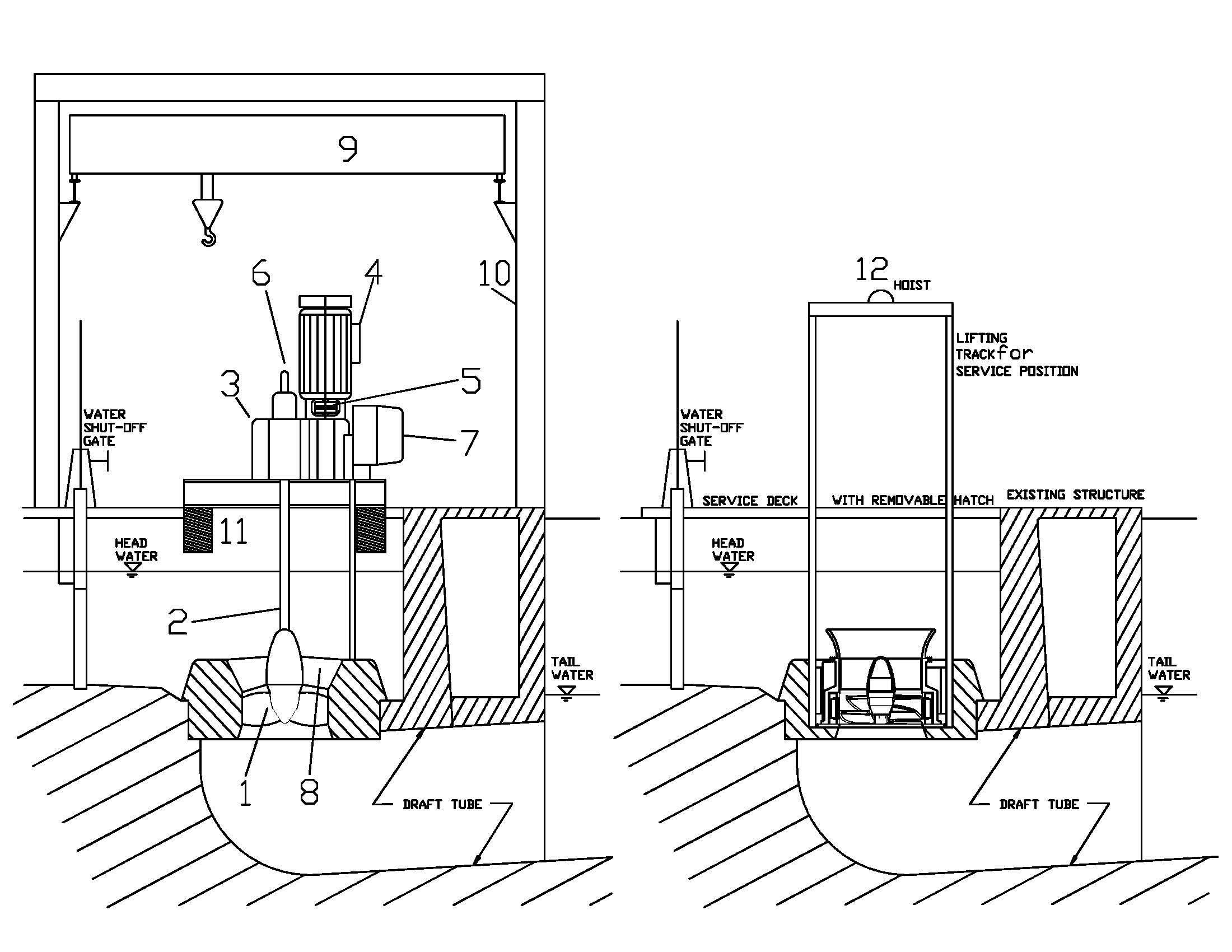

Example Vertical shaft retrofit

Fig.17 The vertical turbine-gear box-generator assembly with frame structure is replaced by an ATS turbine/generator placed over the discharge opening/draft tube. A vertical track allows for the turbine to be raised for maintenance.

Fig. 18 Shows the turbine in place over the discharge opening

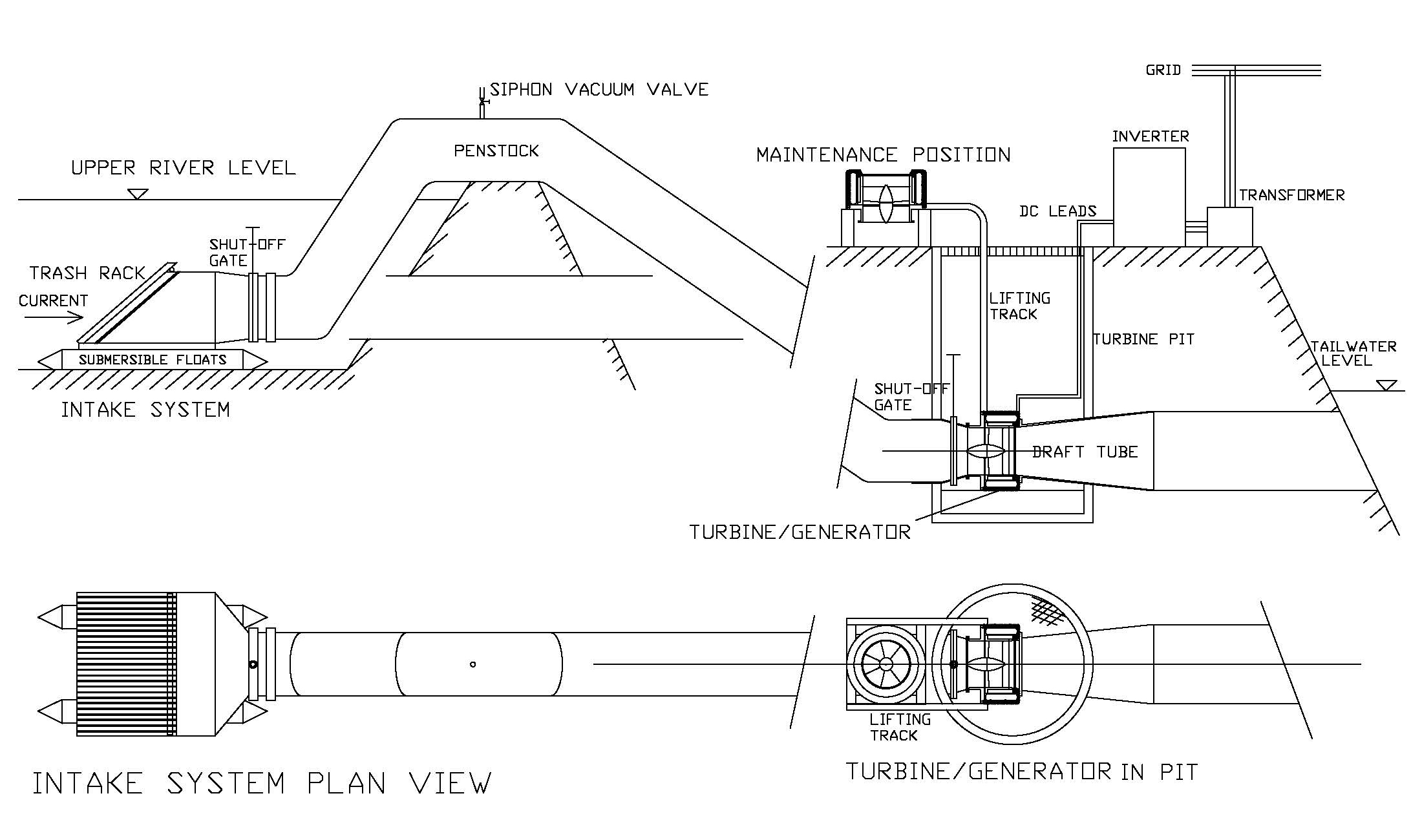

3)-Installation in package in kit form, pit installation

Example Run-of-River Pit installation

Fig.19 This installation includes the intake module with trash rack, intake gate and penstock coupling on one skid. The turbine is placed in a pit to avoid visibility, storm damage and vandalism. The turbine raises on a track for service/replacement.

All components are part of a pre-engineered kit and are delivered on site in a container.